MACHINING

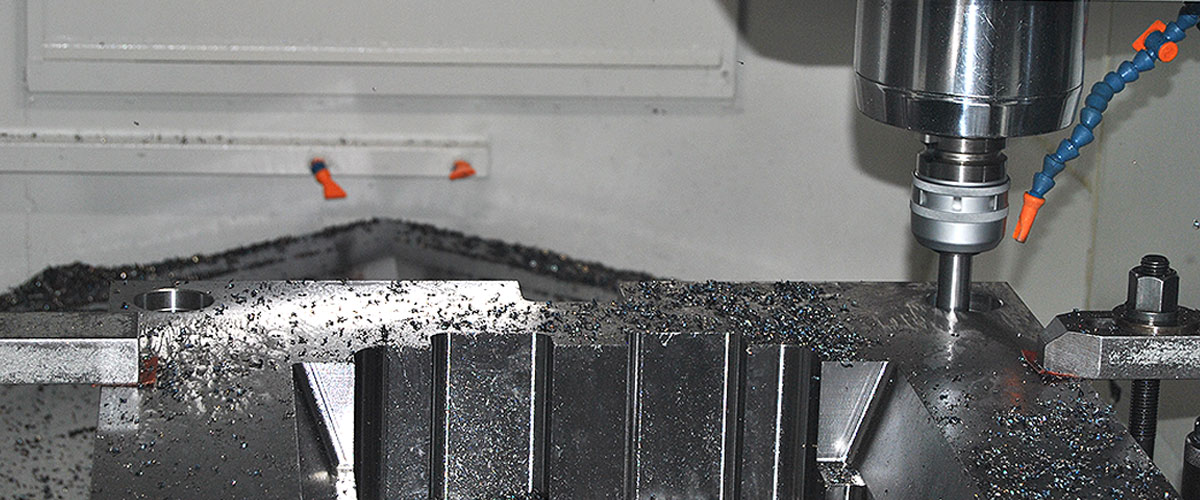

Moldes Picassent uses the latest technology in milling techniques and tools to optimize machining operations, reducing cycle times and producing higher quality surface finishes. High capacity of our machines in milling techniques and programming are an essential part of our manufacturing processes.

We use the most powerful and latest machines that, along with increased programming capabilities, are essential to leverage the latest cutting tools to optimize the time spent on each process and to ensure always an optimum surface finish.

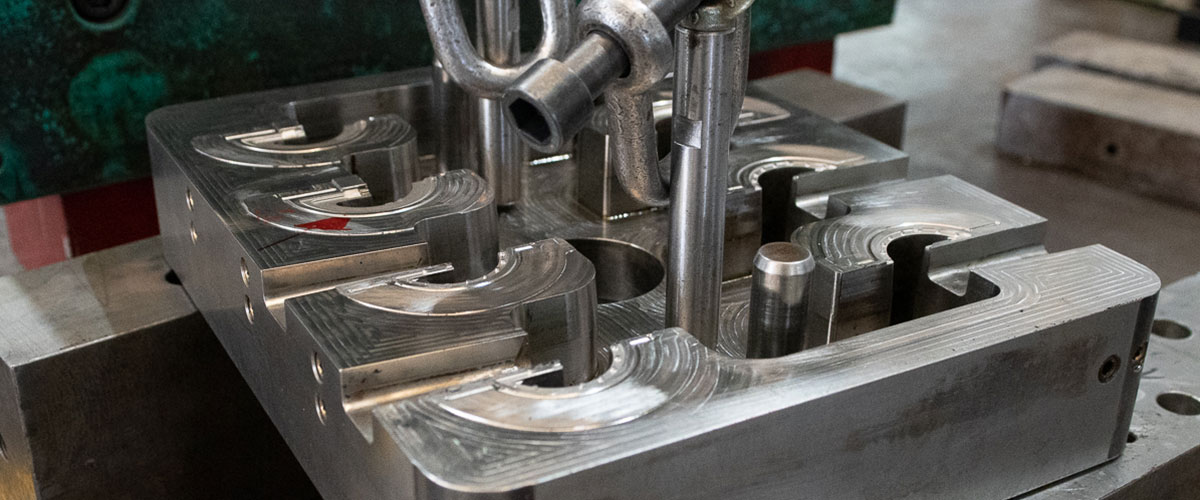

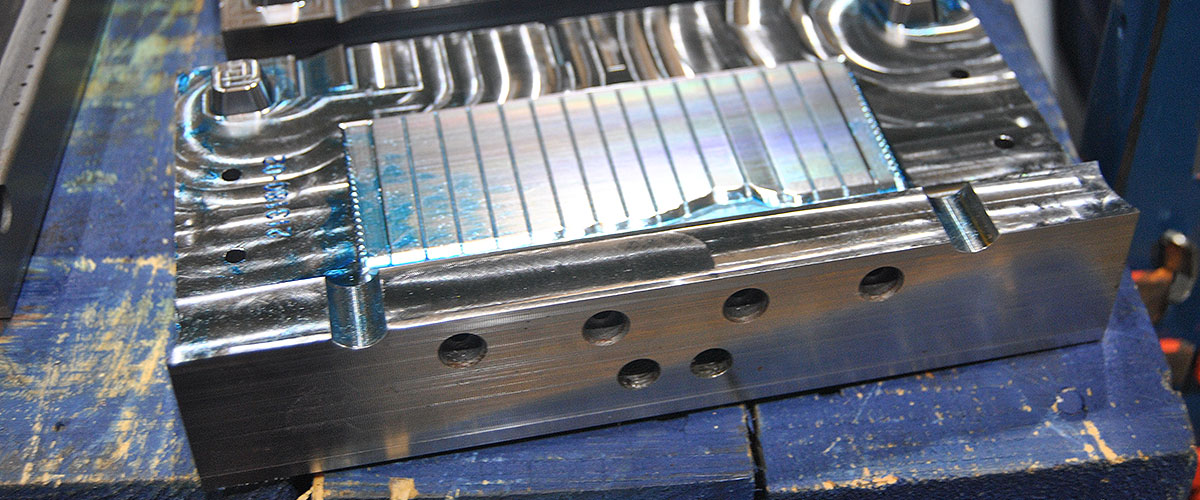

By high-speed milling we can ensure the high quality of the surfaces of our tools.

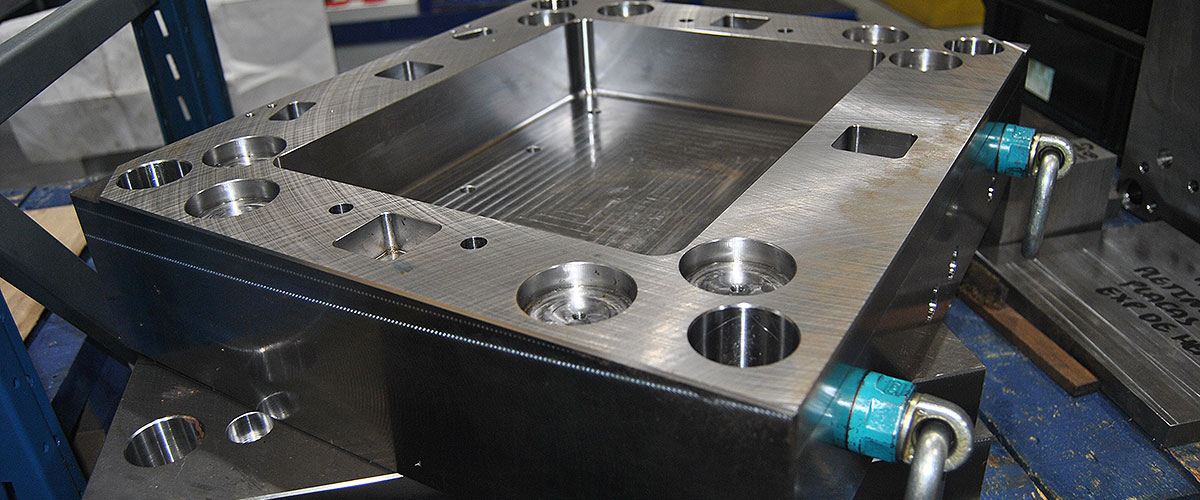

In this way we provide our clients, mainly tool shops, a solution for general machining of mold bases and accessories. We mill for you plates, attachments, strikers, etc.

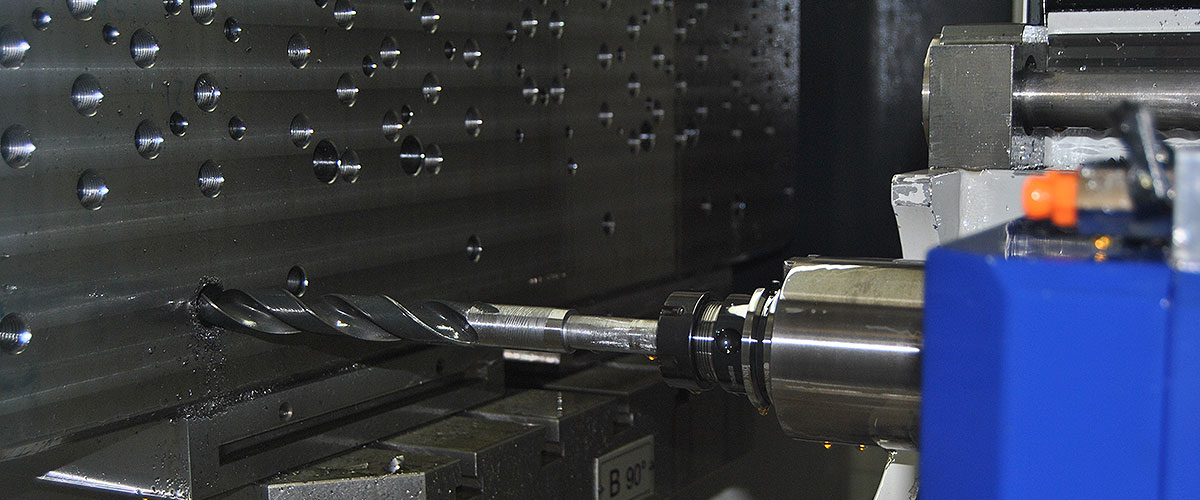

Furthermore, we can do your deep-hole-refrigeracion for cooling, ejector drilling also for inclined lifters , helical drills for all kinds of fittings.

We offer a comprehensive service to shorten your lead time and to strengthen your competitiveness.